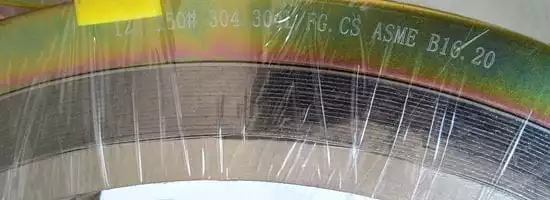

Sealing Principle of Metal Spiral Wound Gasket

A metal spiral wound gasket is a type of mechanical seal that is used to seal two flanges together. It is commonly used in applications where high temperatures, pressures, and corrosive fluids are present. The sealing principle of a metal spiral wound gasket is based on the combination of several elements such as the inner and outer ring, the filler material, and the metal winding. The inner and outer rings of a metal spiral wound gasket serve as a compression stop and a centering device, respectively....